Negative pressure Leak Tester inc|leak testing equipment : agency Vacuum Decay leak testing is used on a variety of products that can only be leak tested at negative pressure. The Optima vT can be used to leak test products, typically less than one liter at a fairly low vacuum, < 0.25 atm. Testing . 19K Followers, 159 Following, 8 Posts - See Instagram photos and videos from Ana Schultz (@anaschultz__)

{plog:ftitle_list}

13 de dez. de 2019 · 近日,韩国CCR公司宣布,旗下开发并发行的科幻题材MMORPG端游《RF Online》开启了“战争点数服务器”。. “战争点数服务器”是《RF Online》在时隔8年 .

pressure decay leak testing equipment

thailand to drop test and go

pressure decay leak test pdf

Understand the pressure decay leak test, an essential technique for identifying leaks in sealed systems.Duct Leakage Testing – RETURN SYSTEM. Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see .Vacuum Decay leak testing is used on a variety of products that can only be leak tested at negative pressure. The Optima vT can be used to leak test products, typically less than one liter at a fairly low vacuum, < 0.25 atm. Testing .

For over 40 years, we’ve provided pressure decay, vacuum decay, mass flow, helium leak, helium recovery and functional test systems to manufacturers around the world. CTS is the .Whether you need a pressure decay air leak tester or highly reliable fluid metering pump, our USA-made leak test fixtures and dispensing pumps will get the job done. Explore your .The Sentinel I28 leak detection system is configurable for a variety of pressure decay testing or mass flow testing requirements. It provides storage for up to 99 pre-programmed test sequences and features a “Parent Program” that holds a .

Cincinnati Test Systems (CTS) designs and manufactures the industry’s most technically advanced, best-performing leak test systems, leak detection equipment, tracer gas systems, . What are negative leak rates? How do they occur? Find out the answers to these questions and more as Russ walks us through an understanding of negative lea.

thanotech drop test

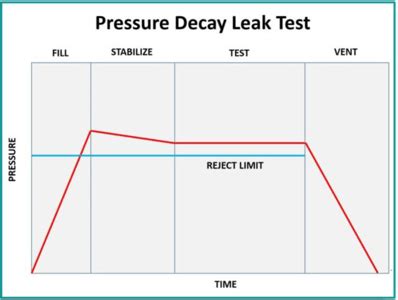

Working principle – general. Enclose sample in sealed an tight chamber. Apply either under- or overpressure to the chamber. Cut the inside of the chamber from vacuum / pressure supply. . Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. It is a simple test that is easy to .Only the negative pressure leak test detected all 54 leaks, a significant difference from the positive pressure test, which detected the least number of leaks, 28 (P < 0.05). Some leak tests are more suitable for specific anesthesia machines. Adoption of the negative pressure test as a universal LPS leak test may prevent the risks associated .Di˜erential Pressure Test Types Differential pressure decay - P Differential pressure decay - leak std ifferential pressure decay - leak rateD ixed Ch - F arge Fill for sealed device esting t. Instrument Highlights. Sentinel I28 leak and flow test instrument. I28 Features. Test Ranges Pressure ranges: -14.5 to 500 psig low ranges: 0.5 to 300 L .

Vacuum and Pressure decay leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH. 2 Overview • Fundamentals of DP method –LFC, P, V (different types) –pressure curve / course . most similar to negative samples (for method development) .Leak Testing 101: A Primer 4 Vacuum Decay Leak Testing Similar to pressure decay leak testing, vacuum decay leak testing evacuates air from the part or system under test to detect leaks. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical .LEADER IN HELIUM LEAK DETECTION Helium Leak Testing, Inc. leads competitors in precision and service. An A2LA Accredited Organization Helium Leak Testing, Inc. is recognized by the American Association for Laboratory Accreditation for safety and quality service. Lean More Multi-Industry Testing Helium Leak Testing, Inc. has multi-industry experience including .

The low pressure system leak test in an anaesthetic machine is an essential component of a pre-test checkout. Although a variety of methods have been described to test for leaks within the low-pressure system, the negative pressure leak test using a suction bulb attached to the common gas outlet is commonly employed for its simplicity, wide applicability .

It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. You can conduct pressure decay testing using either air pressure or a vacuum. Applications for Pressure Decay Leak Testing. As the name suggests, pressure decay leak testing detects leaks by measuring changes in pressure either inside or outside of a part.

If the casing or liner top packer does not have the required integrity, there may be an additional leak path that could jeopardize the production process and even pose danger to the safety of the well. A negative pressure test, also known as the inflow test, is conducted to test the integrity of a well. While carrying out an inflow test, the .

NBC Leak Tester Mk II/Fitment tester is an automated field usage electronic tester which evaluates the fitment (leak tightness) of NBC respiratory full-face mask. This is a Controlled Negative Pressure (CNP) based quantitative fitment type instrument. Salient features: • Micro-controller based system with data storage facility • Consists of .

Vacuum and Pressure decay leak testing Basel, 27. February 2020 Presenter: Patrick Schlatter, WILCO AG, CH Head of Sales Europe / Key Account Manager. 2 Overview . ☺most similar to negative samples (used for method development) Determining the measuring capability of a machine: needle valve ☺adjustable orifice This article explores the negative pressure test in drilling, explaining its importance as a safety protocol and detailing the steps involved. . Any drop in pressure indicates a potential leak or defect in the system. Example: Let's say a storage tank is undergoing a negative pressure test with a specified test pressure level of -5 psi. If .Our leak tester uses a vacuum/negative pressure system to test empty cans. Advantages 1. Our leak testing equipment uses two detectors on the inlet and outlet to measure the negative pressure value. 2. The voltage is generated by the vacuum degree .The most common leak tester fittings are the Male Luer, Male Luer Lock, Female Luer Lock, 5 mm compression, 6 mm compression and the Staubli T. Different Leak Tester Fittings Pressure Range 0–30, 0–100 PSIG of Positive Pressure or 0-14.5 PSI of Vacuum

Fit testing per OSHA Standard 29 CFR Part 1910 or ANSI Standard Z88.2 requires testing in the negative pressure mode using equipment such as a Portacount Plus2 Respira-tor Fit Tester. For this, SCOTT facepieces require use of SCOTT Fit Test Adapter P/N 804057-01 or equivalent and appropriate negative pressure testing equipment.

LEAK-01 Leak tester. Vacuum side leakage method:differential pressure leak test method and bubble leak test method, the product to be tested is put into the leak test box, and the vacuum is drawn on the box body to cause a pressure difference between the inside and outside of the test product. At this time, the following phenomena will occur:5 Varian, Inc. Vacuum Technologies Leak Detection L e a k D e t c t o r s 959 Dry Scroll or Rotary Vane Options as required 1 x 10-4 through 1 x 10-8 2 x 10-9 atm cc/sec 1 Torr Manual Manual---23 (50) Leak testing is a broad term that includes a multitude of technologies. For the purposes of this article, different leak test methods will be referenced but not described in full detail. This article defines the broad term .

Nondestructive Testing, Inc. 1998. 14. Leak Size. Leaks are commonly thought of as HOLES or CHANNELS. Leak size is widely used in pharmaceutical industry as a key characteristic . Dry air leakage rate measured at 1 atm differential pressure across an orifice leak (i.e., leak inlet pressure of 1 atm versus outlet pressure of approximately 1 . Understanding the negative pressure test on a drilling rig is crucial for maintaining control and ensuring safety. This article explains the importance of this test and provides a step-by-step procedure for conducting it effectively. . If the pressure drops, it may indicate a leak in the chamber or a malfunctioning component that needs .

The 1993 Food and drug administration universal negative-pressure leak test is one of them. It was named “universal” because at that time it could be used to check all anaesthesia machines, regardless of the presence or absence of check valves in the low-pressure segment. At present, most anaesthesia machines are compatible with this test.

The pressure increase leak test method can be a good alternative to trace gas methods, given the ability to test parts at very high pressures (up to 1,000 bar), with very short cycle times. . This measuring chamber is not directly pressurized with positive or negative pressure but is dosed via a previously evacuated or filled pre-volume. The .

If the target pressure is not achieved, the PCM concludes that there’s a large leak in the gas vapor system and, after several confirmations, will set a P0455 (gross leak). If the negative pressure exceeds the target pressure, the PCM will set a P1450 for excessive negative pressure, which would likely indicate blocked vapor lines or possibly .

What is a Leak Test? Leak tests, on the other hand, are performed to detect and quantify leaks within a system. Rather than merely identifying weak points, leak tests aim to measure the leak rate or the amount of fluid that escapes from the system over a given period. The Concept of Pressure Decay. In leak testing, pressure decay is a commonly . Incidentally, the test uses only a small negative pressure (vacuum) of around 2 Kpa, or about 0.3 psi. That's not a lot of pressure difference relative to the atmospheric pressure outside the system, but enough to detect a small leak. . If the garage, using a smoke test, found the leak at the valve, I really miss not knowing where the smoke .Learn proper anesthesia machine operation, maintenance, and troubleshooting in this how-to video focused on performing a low-pressure system leak test.

If the anesthesia machine contains a check valve at the common gas outlet, then a negative-pressure leak test should be performed in conjunction with a positive-pressure leak test (see below). A positive-pressure leak test will not detect a leak of the low-pressure components that are upstream from the check valve. Fun Fact: The negative .TEST TYPE : Pressure, Vacuum; TEST RANGE : Pressure(0.1~1.5 bar) / Vacuum(0.1~0.8 bar) ACCURACY : 0.02 bar; WORKING PRESSURE : 0.5~0.6 MPa; DISPLAY : 10.2″ TFT Color LCD with Resistive; COMMUNICATION PORT : RS232C, Start(Input) Signal, Pass(Output) Signal; OPTION : LTE Expansion, Auto Start System, Washer Hose Test System, CH Air Filter

Resultado da From the bedroom to the living area, Alf DaFrè creates furniture with a modern design, for the ultimate quality of living. Discover our collections.

Negative pressure Leak Tester inc|leak testing equipment